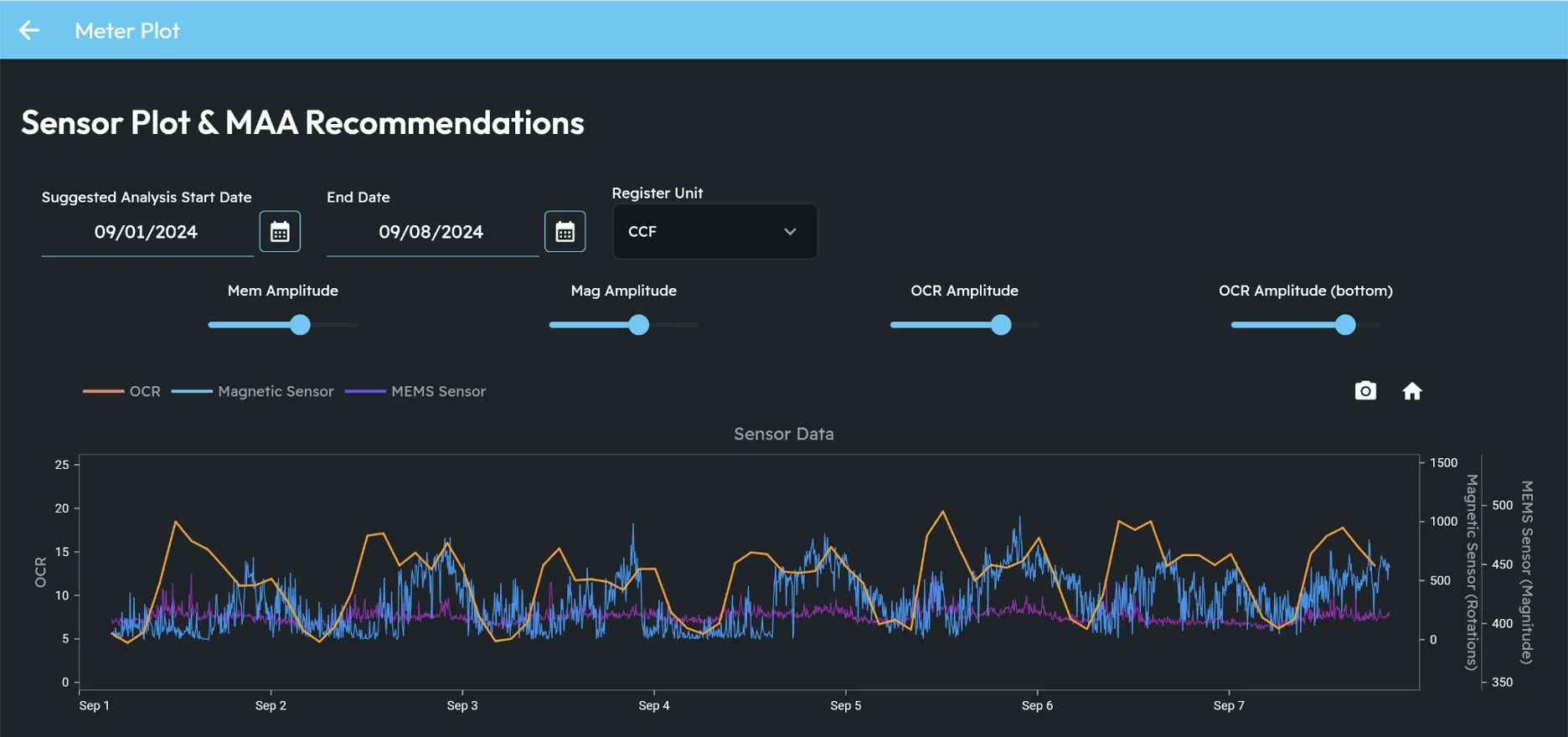

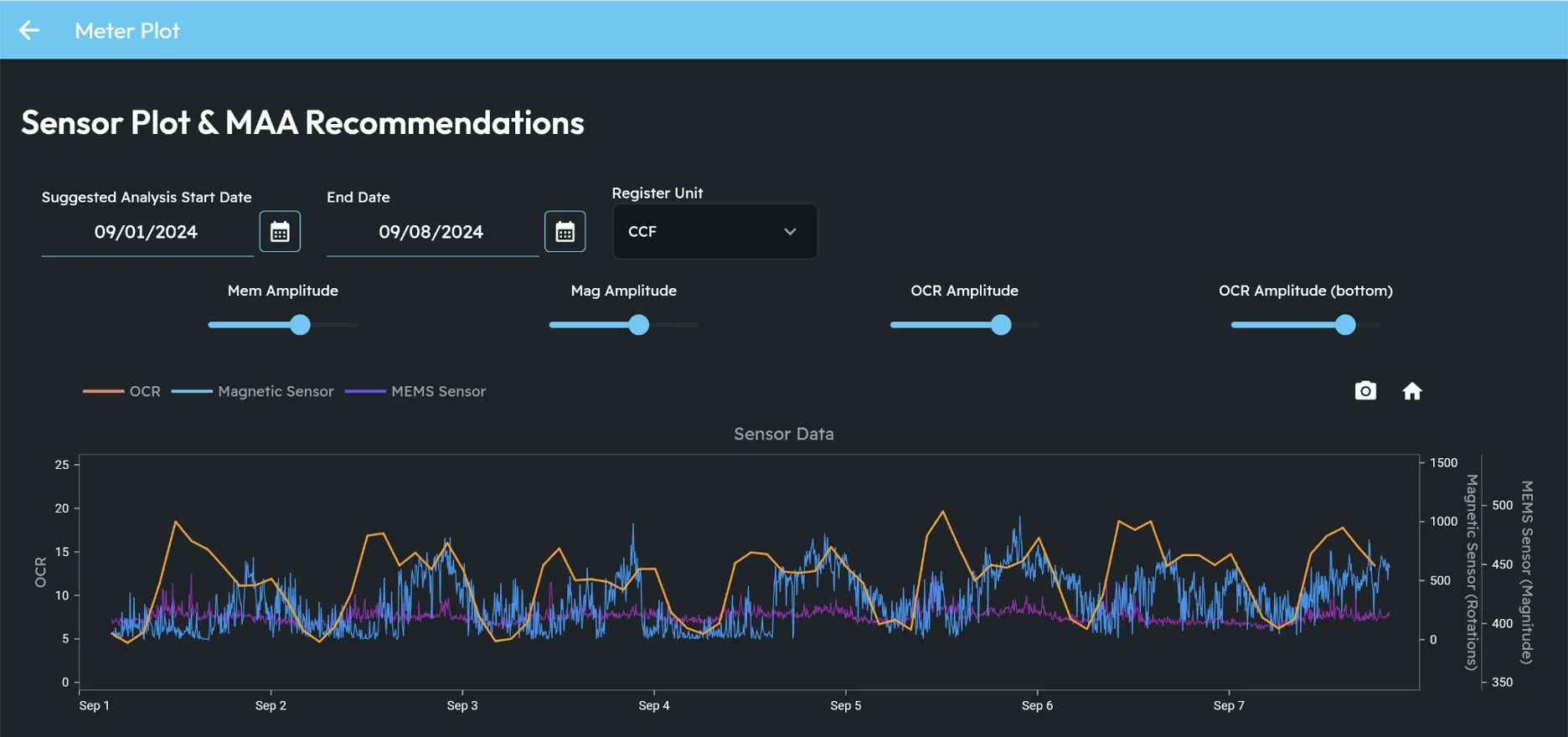

Sensor plots reveal crossover valve issues, measuring element wear, and other anomalies in minutes.

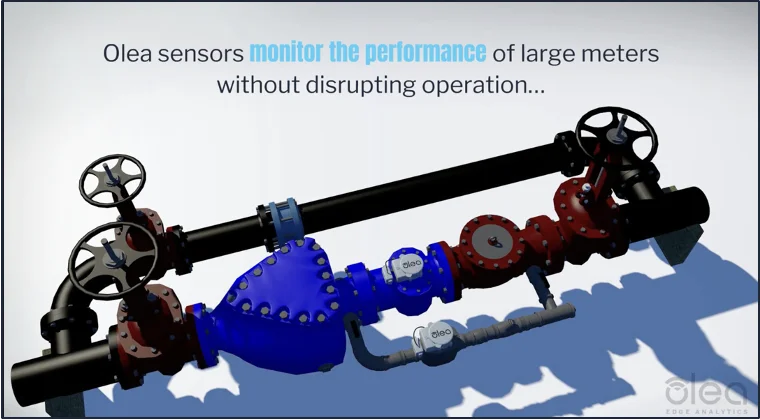

Meter Health Analytics (MHA) keeps the largest revenue meters accurate without disruptive flow tests. IoT sensors and AI-led diagnostics monitor in situ performance, help crews pinpoint root cause, and protect budgets with targeted maintenance.

MHA deploys multi-sensor nodes that monitor flow, pressure, and vibration signatures across a wide range of commercial and industrial meters. AI models benchmark each asset against historical behaviors, flagging under-registration or fouling before revenue loss escalates.

From installation kits to advanced analytics, Meter Health Analytics gives utilities the insight they need to protect revenue and respond fast.

Sensor plots reveal crossover valve issues, measuring element wear, and other anomalies in minutes.

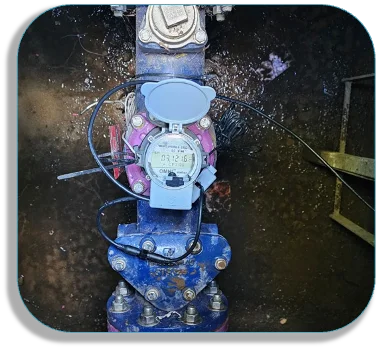

Rugged sensor pods mount directly to large meters without removing them from service.

Weatherproof enclosures protect electronics, even in challenging field conditions.

Quick-connect harnesses simplify installation and ongoing maintenance.

Crews can instrument priority meters in hours and begin capturing diagnostics immediately.

Pair MHA with Olea's PRV Monitoring platform to understand how pressure management affects revenue collection. Joint analytics reveal where transients are degrading meter accuracy and where to focus maintenance crews next.

Customers use MHA to recover missed revenue, justify capital plans, and improve customer trust. These benchmarks reflect typical outcomes in the first year of deployment.

Set up a working session with our analytics engineers to review your largest meters, identify priority districts, and build an implementation playbook that aligns with your budget cycle.